Fox Scientific offers a wide range of materials and sizes of ferrules and ferrule/nut kits. Ferrules are made up of materials and sizes depending on the use of the ferrule. The materials that are available are 100% graphite, 15% graphite/85 % Vespel ®, SilTite ™ metal ferrules and kits and SilTite ™ FingerTite ferrules and kits for Agilent, PerkinElmer, Shimadzu, Thermo Scientific and Varian/Bruker GC's. Sizes range from 1/16 " with various hole sizes to 3/8 ". You can see the various ferrule requirements for your system in the Guides at www.foxscientific.com/sge/ .

Please contact Fox Scientific at 800-369-5524 for help in selecting the proper

ferrule, septa, cap or kit for your needs.

Septa must be chemically compatible with your sample and solvent to ensure they provide an

effective seal. The table below summarizes the suitability of each septa material with a range of

chemicals, this can vary based on factors such as temperature, molecular weight and solvent

concentration.

Trajan septa undergo conditioning (thermal and chemical) to reduce siloxane bleed. Siloxane

bleed can occur during heating, solvent interaction or piercing by the autosampler needle

causing the material to become stressed.

Septa materials available from Trajan

| • Silicone - Highly inert. - Excellent resealing. - Recommended for HPLC and GC, where purity and resealability are critical. - Max temperature of 250°C. - Not recommended for use with lipids due to siloxane bleeding caused by stress on the material. • Silicone with PTFE film - PTFE has superior chemical inertness and lower permeability which ensures protection of the silicone from harsh chemicals. - Recommended for aggressive solvents. - Increases resistance to coring. - Can have PTFE film on one or both sides. • Silicone with polyimide film - Polyimide has a 300°C temperature tolerance, ideal for methods requiring high temperatures. - Good resealability, recommended for methods involving multiple injections or long run times. • Foam - Long term storage in closed top cap. - Not used for needle penetration. |

• Silicone with FEP film - FEP has high chemical resistance, used when the sample is sensitive to PTFE exposure, making it the recommended material for corrosive or chlorinated samples. • Butyl - High density and intrinsic hardness provides an improved barrier between the sample and atmosphere. - Recommended for use with volatiles and inorganic gases. - Susceptible to coring, depending on needle type and size. - Intrinsic hardness can be challenging for automation. - Best needle penetration force compared to silicone rubber. • Viton - High chemical resistance, recommended for use with chlorinated solvents. - Has an intrinsic hardness, making it unsuitable for 23 gauge needles or high injection speeds. - Maximum temperature of 260°C. |

Septa thickness

Thicker septa give improved resealability, for methods which involve multiple injections or long running times. Trajan septa are available in a range of thicknesses from 0.25 mm to 4 mm.

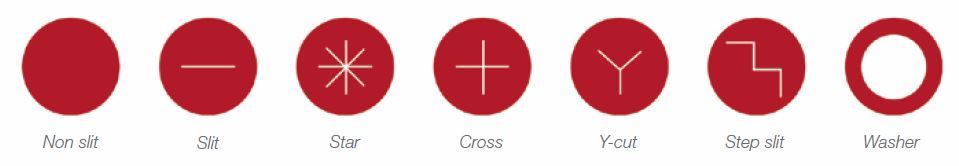

Septa configurations available

• Non slit

- Non slit septa typically have resealing capabilities, but only for a limited number of needle punctures.

- Recommended for long-term storage of samples.

- Help reduce carryover between vials as the septa wipes solution from the outside of the needle as it exits the vial.

• Slit

- Pre-cut slits reduce the pressure required for penetration by the autosampler, reducing the number of bent or broken needles.

- Help to avoid suction when drawing large volumes of sample from the vial.

- Recommended for use in LC because they prevent the injector from becoming blocked.

- Reduces coring.

- Solvents in LC evaporate slowly so they will not leak from the pre-slit septa.

- Reduces needle bending during solid phase micro-extraction (SPME).

- Holes added for direct insertion SPME. These do not need to be added for headspace SPME.

Pre-assembled caps and septa reduce handling and therefore contamination. Custom color combinations, materials, and geometries available upon request. Aluminum crimp caps provide a leak-resistant seal.

Use of a crimping tool is required for aluminum seals. Magnetic crimp seals for use with autosamplers.

Snap caps are easy to apply and remove without tools, eliminating the need for crimping tools.

Cap types

| • Crimp caps - Crimp caps provide extra security for studies where it is important to avoid contamination or sample tampering. - Can become rounded when crimped onto a vial, resulting in less surface area for magnets to stick to during automation. - Require crimper/decrimper, can cause septa distortion if overcrimped. • Snap caps - Simple snap design when crimping tool is not available. - Easy removal without special tools. |

• Screw caps - Often used for LC and LC/MS. - Provide an airtight seal. - For automation, magnetic screw caps are advantageous because they are less likely to become rounded over time, providing increased surface area for the magnets used to move the vials. This decreases the risk of any vials falling from the magnet. |

Cap materials

• Polypropylene

- Melts at 130°C and becomes brittle at freezing temperatures, therefore is not suited to procedures requiring large temperature ranges.

• Aluminum

- Metal caps have the highest ranging temperature tolerance and are resistant to impact.

- Aluminum is used for crimp seals.

• Tin/steel/nickel coated

- Magnetic so recommended for use with autosamplers and other forms of automation.

- Tolerant of both high and low temperatures.

• Bimetal

- Two layers of separate metals joined together.

- Excellent temperature tolerance.

- Magnetic pick up.

• Phenolic

- Maximum temperature of 220°C, starts to decompose at higher temperatures.

- Non-reactive, making phenolic finishes beneficial when using corrosive or harmful chemicals.

Fox Scientific, Inc.

8221 East FM 917

Alvarado, TX 76009

Phone: (800) 369-5524 * Fax: (817) 783-3571

sales@foxscientific.com

www.foxscientific.com